Organic Farmer/ Green Energy Expert A father, a husband and…

Read Next

In this issue we shall take look at how to make compost. Compost is made using plant material and is in effect giving back the soil what the plants took from it.

Compost is an exceptional alternative to fertiliser, which builds up not only the organic nutrient levels in the soil, but helps to restore the natural biotic balances which occur in the soil profile. 2 Corinthians 9:8 “And God is able to make all grace abound to you, that always having all sufficiency in everything; you may have abundance for every good deed.” God’s Word is true. He has made a way for everyone to have the best quality soil supplement… Compost. By putting back good quality compost into the soil, farmers can reap better, profitability in the long term even when comparing to fertiliser usage.

What is Compost?

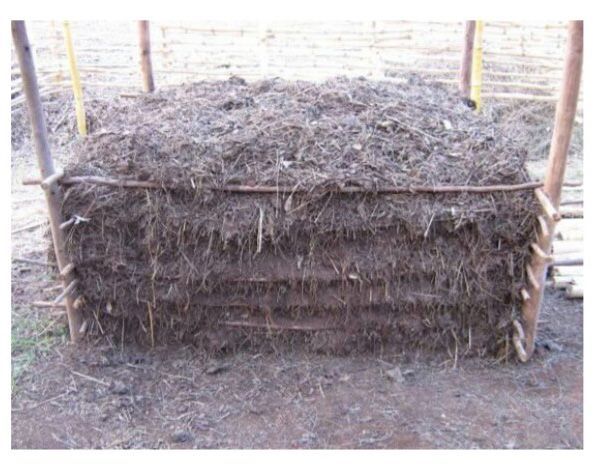

Compost is simply decomposed organic matter that has been broken down by micro organisms, especially bacteria and fungi. To ensure that our compost is of the highest quality we must follow strict standards and stick to the recipe. We suggest a compost pile size of 2m long by 2m wide by 2m high.

This is small enough for a single person to work in a few hours, while allowing for adequate internal temperature of the pile. This compost volume will easily be enough for an acre or half a hectare of maize. It is not recommended that you reduce the size below 1.5 m cubed.

Ingredients

Compost is made of three main ingredients nitrogen, green and a woody/dry component.

1) Nitrogen Component: Nitrogen is the fuel of the compost pile and gets the bacteria going. The Nitrogen component should make up 10% of your pile and you can use 15 bags of manure. If there is no manure in your area then you can use 4 m3 of legumes for this and just adjust your green and woody/dry components accordingly

2) Green Component: Green leaves are the source of sugars, which are necessary for good quality compost. The green component should make up 45 % of your pile and anything that is cut when green, even if it has dried, is classified as green.

3) Woody Dry Component: The woody material really helps to encourage the fungal growth in the pile because it breaks down so slowly and keeps the pile aerated, while the dry material adds bulk. The woody dry component equals the green component and makes up the balance of 45% of the pile.

Woody materials include maize cobs, stalks, branches, cardboard and wood shavings, while dry material includes thatch grass, leaves and weeds.

To summarise the ingredients we need: 15 bags of manure and an equal split of 45% green to 45% woody dry. The materials should be piled separately until such time as enough of each material has been accumulated. Collecting enough material to build a pile takes time, so you must just plan properly. Farmers should get themselves into groups of five to pray and help one another.

Building the Pile

When building the pile, it is very important that the right ratios are maintained. The simplest way to achieve this is to build using alternate layers of the 3 main ingredients. Dunk the green and woody/dry materials in a container of water before you place them, so that you wet the layers thoroughly. A good wetting at the outset will mean you will probably only need to add water maybe once or twice in the 2 month process.

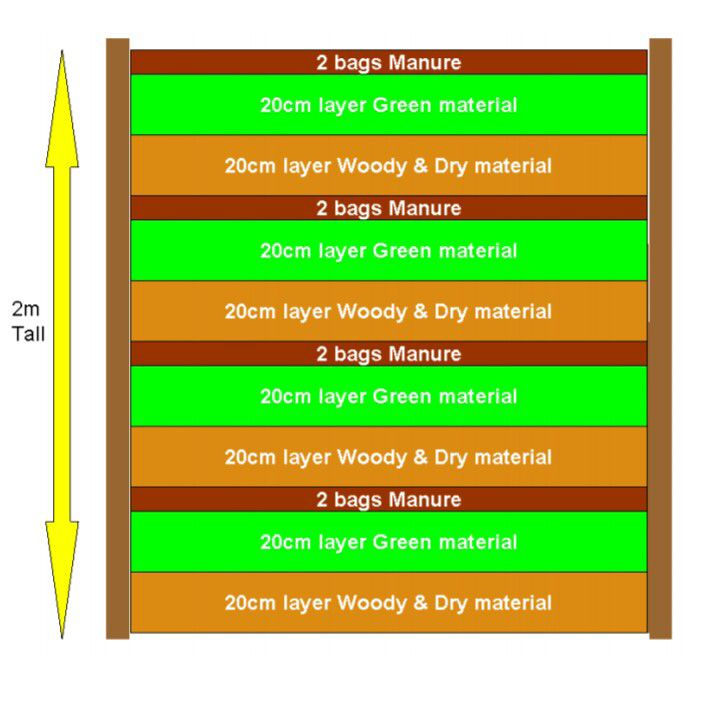

Start with 20 cm of woody dry, then place 20 cm of green, then 2 bags of well wetted manure on top of that. Continue repeating the layers until you get to the 2m height.

Diagram 1

PIN IT

PIN IT

Turning the Pile

Within 3 days, the compost pile will have heated up and needs to be turned. The best way to do this is to mix the pile into the adjoining 2m *2m position, using a fork or a hoe. The turning process maintains the correct temperature, mixes all the ingredients, brings material on the outside to the inside, aerates the pile with oxygen and allows for moisture levels to be checked and adjusted if necessary. If the pile is not turned it will become anaerobic, have a bad smell and result in poor quality compost.

Temperature

The compost gets hot very quickly because of all the bacterial activity. The ideal temperature of the compost should be maintained between 55C to 68C for 3 days, to kill all seeds and unwanted pathogens. If you don’t turn your compost, the temperature can easily reach 70C, which is too hot and kills off the desirable microbes, as well as burning up and wasting carbon. The most accurate way to determine the temperature is by using a temperature probe. Turn the pile before the temperature reaches 70C.

A cheap alternative would be to use an 8 mm steel rod. After inserting it for a few minutes see if you can hold on to it for 5 seconds. If you can, the temperature is less than 70, if not it’s ready for another turn. A really simple guideline is to turn the compost pile every 3 days for the first 3 turns and every 10 days for the next 4 or 5 turns. The temperature goes down after each turn and rises again until the next turn. This cycle will continue until all the nitrogen in the pile has been utilized. If you followed the guideline ingredient volumes of 15 bags of manure, then the compost will get hot enough for adequate decomposition and also will be maturing and cooling after 6-8 weeks.

Mixing

Mix the different materials thoroughly and bring the materials on the outsides into the centre so that it also gets exposure to high temperatures. When turning the pile, test to see whether it is moist enough, as a lot of moisture is lost as steam and these needs to be replaced. Try to keep the moisture content of your compost at 50%. You can test this by squeezing it in your hand. If moisture drips out, it is too wet. If no water drips out, but on opening your hand the material does not hold its shape, then it is too dry, so add water. If squeezed, and no extra moisture drips out and on opening the hand the material holds its form, then it is close to the desired 50% moisture content. Leave a gentle slope on the top of the pile and place thatch grass or grain bags on top to keep excess rain water off the pile, which can cool the pile too much.

Indicators of Good Compost

After 2 months the turning process is complete, but it should be left to cure thoroughly for another 4 months before you can use it. When complete, your compost should be a dark brown color, smell sweet and rich have a crumbly structure and you should be able to see thick fungal strands. When mature, the compost can be stored as is for years without degrading or losing its nutrients. You don’t need to turn it anymore, but remember to check the moisture levels regularly. At this stage your compost will be in the form of stable organic nutrients and inoculum.

Diagram 2

PIN IT

PIN IT

Utilizing the Compost

For maize, dig the holes to 15 cm deep, then place 350 ml per planting station and cover with soil to a 5 cm remainder. The yield potential using good quality compost is well over 5 tons per hectare and the cost of producing it is only labour used. The record yield with Farming God’s Way using compost only on virgin soils has been 8 tons per hectare. Compost is the input that we should see on every farm field as we teach farmers faithfulness with what God in His all sufficiency has put in our hand.

Source: Farming God's Way training manual.

Subscribe now for updates from Msingi Afrika Magazine!

Receive notifications about new issues, products and offers.

What's Your Reaction?

PIN IT

PIN ITOrganic Farmer/ Green Energy Expert A father, a husband and a son of God. He runs Viro Mental Ltd, a renewable energy and organic farming business. He ran a Solar and power solutions business for the last 12 years. In 2013 He answered God’s call to be a farmer and embarked on a learning process that has led to him seeking to be a qualified trainer in Farming Gods Way. PASSION FOR THE ART I love farming and green energy I am passionate about doing it in God’s way.