Beyond steel, nails and glue: Traditional woodworking techniques inspiring Sustainable Building Design

I offer sustainable design and construction services as a construction…

Ancient woodworking techniques such as Sashimono, renowned for its precision-crafted, interlocking joints, has become a celebrated practice in sustainable furniture design. Its principles of durability, health-consciousness, and environmental sustainability could have transformative implications beyond furniture, especially in the construction industry, with a particular focus on architecture.

These techniques invites us to rethink material use, structural integrity, and design aesthetics. By applying these principles, we can build spaces that are not only functional but also aligned with sustainable and regenerative architectural practices.

1. Exploring Woodworking Techniques for Sustainable Joints

Japan’s Sashimono method is just one of many techniques that can transform modern construction. From dovetail joints in carpentry to tongue-and-groove systems in traditional flooring, these methods enable strong connections without relying on nails, screws, or adhesives—offering opportunities for sustainable and innovative architectural applications.

a) Sashimono (Japan): Sashimono involves precisely crafted interlocking wooden joints, requiring no adhesives or nails. Its legacy can be seen in traditional Japanese furniture and architecture, where durability is achieved through tight-fitting joinery that resists wear over time.

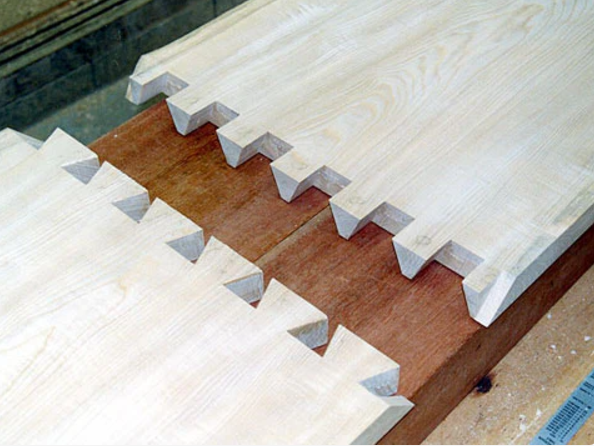

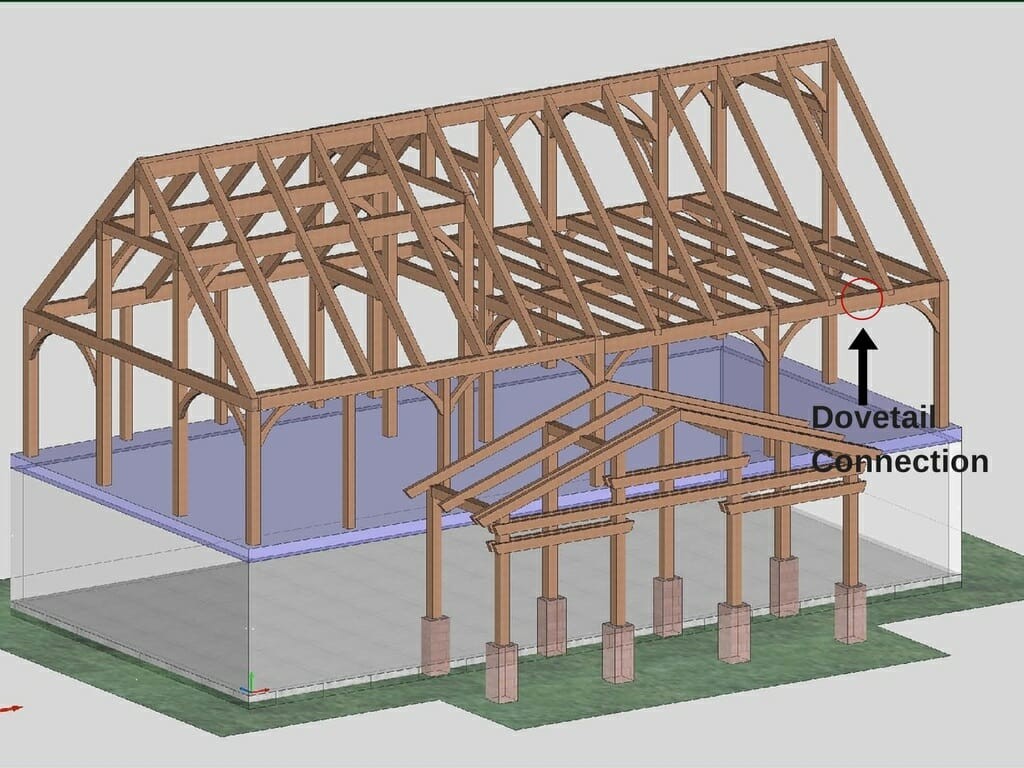

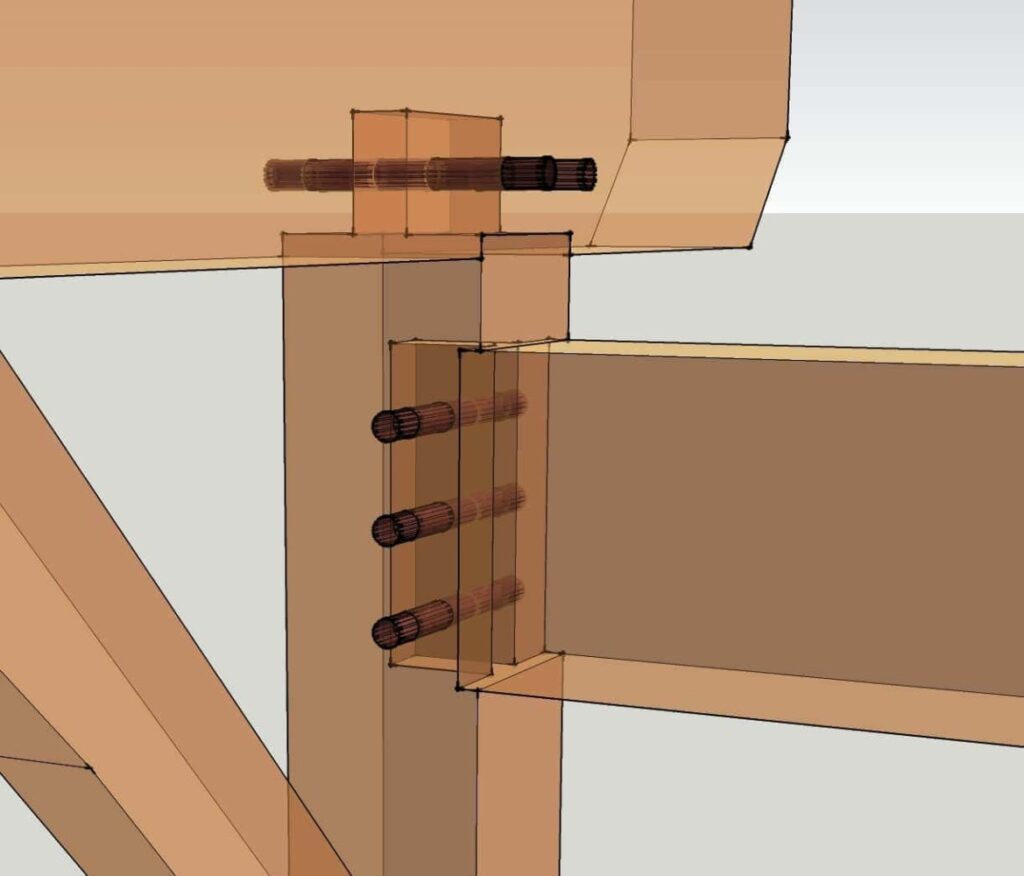

b) Dovetail Joints (Global): This technique uses wedge-shaped interlocking fingers, commonly found in cabinetry and traditional timber framing. Dovetails create mechanically strong bonds ideal for load-bearing walls and roof structures.

c) Mortise-and-Tenon Joints (China and Europe): Widely used in historical buildings, this joint involves a projecting tenon fitting snugly into a mortise hole. It is particularly suitable for structural frameworks like columns and beams, offering remarkable strength and longevity.

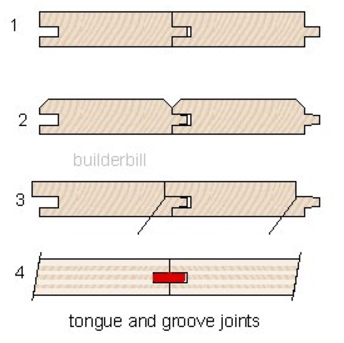

d) Tongue-and-Groove (Global): Frequently used in flooring,ceilings and paneling, this system creates seamless and durable surfaces without visible fasteners. The technique also reduces material waste and simplifies assembly.

Above are four versions on the theme of T&G joints as they are sometimes called:

- A basic joint. One side has a groove machined in it and the other has a tongue.

- “Vee” jointed boards are used on wall panels or outside doors to make a feature of the joints, rather than trying to hide them.

- This is a modern profile that is optimised for secret nailing. The position of the nails are shown, and you can see that there is more timber for the nail to grip tan in the first example.

- This is a section of flooring ply. The ply sheets have a groove around the outside edges and a loose tongue is fitted into the grooves.

e) Butterfly Joints (Asia and Europe): These are decorative and functional, used to join slabs of wood while preventing splitting. They could be integrated into architectural features like exposed beams or decorative elements in ceilings.

Key Benefits

1. Enhanced Durability for Architectural Structures

Interlocking joints create strong connections without the use of glue or nails, resulting in components that maintain structural integrity over time. In architecture, this approach could be used to construct timber frameworks or modular components for buildings that withstand significant stress, seismic activity, or prolonged use.

For example, interlocking wooden beams could replace conventional fasteners in roof trusses or load-bearing walls, providing buildings with increased longevity and resilience. This approach echoes traditional Japanese timber architecture, where temples and pagodas have withstood centuries of wear and natural disasters without relying on modern adhesives or nails.

2. Health-Conscious Building Materials

Modern construction heavily relies on synthetic adhesives, treated metals, and composite materials, many of which emit volatile organic compounds (VOCs). These compounds degrade indoor air quality and pose long-term health risks. By integrating woodworking techniques, untreated, natural timber can be used to construct interior elements like flooring, partitions, or cabinetry, reducing chemical exposure for occupants.

Such practices align with biophilic design principles, promoting healthier indoor environments while connecting inhabitants with nature through the use of organic materials and textures.

3. Sustainability Through Recyclable and Repurposable Design

Buildings generate significant waste during demolition, much of which is difficult to recycle due to contamination from adhesives, metals, and composite materials. Use of pure wood techniques and detachable joinery offers a solution by enabling the easy disassembly and reuse of building components.

For instance, modular walls or flooring systems made with interlocking joints can be taken apart and reassembled in new configurations, reducing material wastage. Additionally, the absence of chemical contaminants makes the wood easier to recycle or biodegrade at the end of its lifecycle.

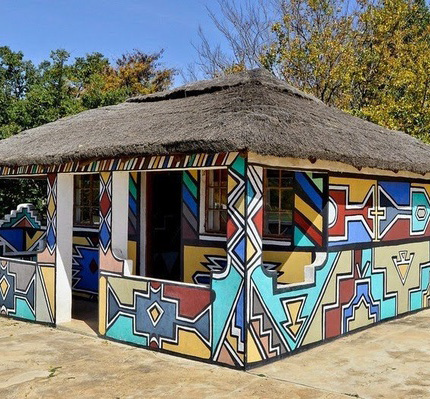

4. Organic Aesthetics and Architectural Elegance

Incorporating such techniques into modern architecture can enhance a building’s aesthetic appeal. The exposed joinery highlights craftsmanship and brings an authentic, organic look to interior and exterior spaces. This design philosophy aligns with contemporary trends that favor minimalism, natural materials, and a connection to heritage.

Architects could use visible interlocking joints as decorative elements in beams, columns, or staircases, showcasing the beauty of the materials while celebrating sustainable design.

Case Studies of Traditional and Modern Applications

1. Hōryū-ji Temple: A Testament to Sashimono’s Strength

Located in Nara, Japan, the Hōryū-ji Temple (607 CE) is one of the world’s oldest surviving wooden structures. Its construction showcases advanced Sashimono joinery, where interlocking wooden pieces ensure stability without nails or glue. This technique enables the building to withstand Japan’s frequent earthquakes, as the joints flex without breaking.

The temple’s pagoda design uses mortise-and-tenon joints alongside Sashimono interlocks, ensuring that each tier distributes weight evenly and resists lateral forces. The absence of synthetic materials enhances its environmental footprint, as the structure is fully biodegradable and easily repairable—a stark contrast to modern materials that complicate recycling.

Hōryū-ji exemplifies how traditional woodworking techniques can foster resilience and sustainability in construction while maintaining cultural heritage.

2. Mjøstårnet: Modern Timber Engineering with Timeless Principles

Standing at 85.4 meters, Norway’s Mjøstårnet is the world’s tallest timber building. While it primarily uses glued laminated timber (glulam) and cross-laminated timber (CLT), its construction echoes ancient principles of interlocking and prefabrication.

The building’s beams and columns use mortise-and-tenon-style connections, ensuring mechanical strength and allowing modular assembly. Prefabricated panels reduce on-site waste, while the absence of steel fasteners in some sections mirrors Sashimono’s reliance on natural fits.

Mjøstårnet’s achievement highlights how traditional woodworking techniques, adapted for modern engineering, can scale sustainably. Its use of timber sequesters carbon, and the structural systems demonstrate how joinery principles can reduce reliance on energy-intensive materials like concrete and steel.

3. Architectural Applications of Woodworking Joinery

- Load-Bearing Structures: Mortise-and-tenon or dovetail joints can replace metal fasteners in timber-framed walls and roofs, creating durable frameworks with minimal materials.

- Prefabricated Modular Units: Techniques like tongue-and-groove or Sashimono interlocks are ideal for prefabricated wall panels and flooring systems, which can be assembled and disassembled with ease, reducing waste during renovations or relocations.

- Decorative Elements: Butterfly joints or exposed dovetails add aesthetic appeal to beams, staircases, or furniture, emphasizing craftsmanship while maintaining structural integrity.

- Seismic-Resistant Designs: Buildings in earthquake-prone regions can benefit from flexible, interlocking joints like those used in Hōryū-ji, where joinery absorbs and redistributes seismic forces, reducing damage.

A Sustainable Future Rooted in Tradition

Reviving woodworking techniques like Sashimono, dovetails, and mortise-and-tenon offers a pathway to more sustainable construction practices. These methods not only reduce dependence on synthetic materials but also promote the use of renewable resources, improve recyclability, and celebrate craftsmanship.

Incorporating these techniques into architectural designs—whether in heritage restorations or modern timber skyscrapers—enables us to build structures that are durable, adaptable, and environmentally responsible. As the success of Hōryū-ji and Mjøstårnet shows, traditional woodworking methods can meet the challenges of contemporary construction while fostering a sustainable connection to our built environment.

By bridging the gap between ancient practices and modern needs, we can craft buildings that honor tradition and innovation, offering timeless solutions for a sustainable future.

What's Your Reaction?

I offer sustainable design and construction services as a construction project manager and quantity surveyor. I focus on using sustainable materials for building. You can reach me at rnmbiu1@gmail.com